SKIP TO THE BOTTOM FOR RECOMMENDATIONS

Let’s assume you’ve already done your research and want to get serious about screen printing. Maybe you’ve watched a few youtube videos, maybe you’ve even burned a screen and tried printing with a DIY or tabletop rig. In any case, you’ve landed here- you’ve decided to buy a press. The guide below holds some considerations and recommendations that will hopefully help you out moving forward.

Size

Presses come with various amounts of print heads and stations. Typically, this is abbreviated as a fraction with the top number being the amount of heads and the bottom number being the amount of stations (ex. a “4/1” press has 4 heads and 1 station).

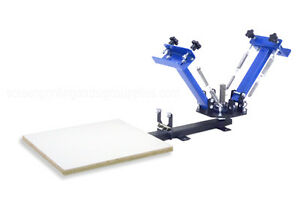

The smallest and cheapest press you could get would be a 1/1. It limits you to a one color print, as there is only one printhead, and the workflow is fairly slow. You can pick these up for around $100-200, but most people grow out of them in a matter of months because they want to print more colors.

The next step up is a 2/1 or, more commonly, a 4/1 press. Four print heads allow you to print up to four colors at once, and the single station makes it small enough to fit in tight spaces. Most presses this size are table top presses- meaning they’re lightweight and don’t have legs.

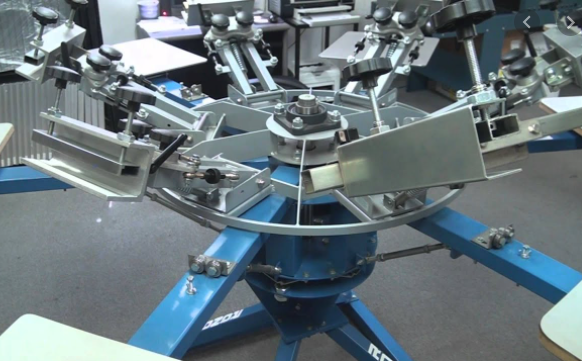

After that, you reach the multi station presses. These presses have both a rotating printhead section, as well as a rotating bottom portion with platens. 4/2, 4/4, 6/6 and on, with rotating platens that allow you to work with a partner or simply speed up your own workflow.

Think about how you plan to use your press. If you’re just a hobbyist or run a small etsy shop, you might be able to get away with a 4/1 or even a 1/1. However, if you’re trying to grow a custom printing business and will regularly be getting orders in the dozens or hundreds of pieces, the time saved by having multiple platens will make it a worthy investment.

Brand

Screen printing presses are one of those products where brand matters, and you’ll only hurt yourself in the long run by “cheaping out” and buying inexpensive equipment. There are a ton of cheap, Chinese made presses flooding eBay, craigslist, and even Amazon. Some of them have decent reviews, others even have Youtuber endorsements. Don’t get caught up in the hype.

Most people post a review on Amazon within a few weeks of receiving a product. A screen printing press is something that you buy with the expectation of using it for years on end, through thousands of prints. It’s not something you can evaluate as soon as it’s out of the box.

In the short term, these (mostly blue) presses from overseas may look nice. They may even work for simple, one color prints. However, as soon as you move into multicolor or more complex printing, issues begin to appear. They don’t hold registration, the off-contact unexpectedly changes, the springs loosen… Screen printing is hard enough with the right equipment, don’t screw yourself over by buying junk.

Before you buy anything, refer to t-shirtforums or a facebook group with seasoned professionals. Check to see what others have said about the brand you’re considering purchasing. Buy from a company that specializes in making presses, like Vastex, M&R, Workhorse, or Riley Hopkins.

Used or New?

Screen Printing presses are industrial tools. Presses by the brands mentioned above are built to function every single day for hours on end, and to last decades. They are also fairly simple machines- consisting mostly of welded metal, as well as some bearings and springs. There’s not much that can go wrong on them.

With that said, buying used is a great way to save money on higher end equipment. Large presses, especially 4/4s and 6/6s can cost thousands of dollars brand new, but regularly pop up on the used market for under a thousand dollars. If you’re looking for a larger press, check facebook marketplace and eBay regularly as you might be able to snag an older press for a fraction of its initial MSRP.

When buying smaller, hobby style presses, however, you may want to spend that extra $100 and get something new. 1/1 and 4/1 presses are already fairly inexpensive, and it’s worth spending a little more money to get a good warranty, customer support, and the guarantee that your press will work out of the box with minimal adjustments.

Other considerations

Perhaps the most important “feature” a press can have is micro-adjustments. Printheads with micro adjustments allow you to move the printhead using knobs or levers on the back, to help with aligning designs. For very detailed, multi-color jobs, they are a must. However, few entry level presses have them and they’re almost unnecessary for 1-3 color prints. Think about what kind of designs you plan to print. If you’ll be printing mainly 1-3 color, basic logos and text designs, you may not need micro-adjustments. If you’re an artist or work with brands that regularly use halftones and designs that require perfect registration, you may need to fork out some extra dough.

What do I recommend?

Lower End (1/1)

From a manufacturing perspective, a 1/1 press is hard to screw up. Unlike multi-head presses, a press with a single head doesn’t have many moving parts and doesn’t need perfect registration because you’ll only be printing with one screen. Additionally, it’s rare for people to buy a 1/1 and not upgrade in a matter of months anyway, so the bar is pretty low.

If you want, you can take a gamble on a $50-70 Chinese press off of eBay. Maybe you’ll even be able to snag a used one for less than $50. Expect some issues with printing thicker inks like plastisol white, and the possibility of it completely crapping out after a couple months. You get what you pay for.

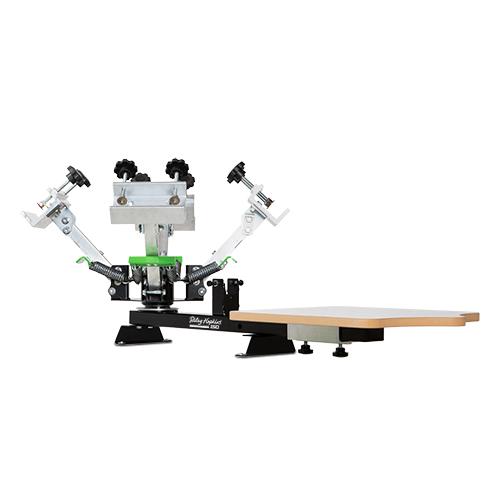

If you don’t anticipate upgrading for a while, you’re okay with being limited to one color, and you need something that will have tight registration and no issues- consider the Riley Hopkins 150 1/1. It’s a solid press and will last years, but you’ll quickly grow out of it and with you had spent $200 more bucks on the 4/1.

Middle Range (4/1)

If you’re looking for a 4/1 press, the Riley Hopkins 150 4/1 is a clear winner. Full stop, no debate. For $399 plus shipping you get a press with four solid print heads, tight registration, adjustable off contact and a decent wood platen. Unless you find an insanely cheap, used press by M&R or another big manufacturer, you won’t find a better deal.

The Riley Hopkins 4/1 doesn’t have micro adjustments, which may be a turn off for some people, but it has a tight registration gate so you’ll still be able to line up even very complex designs with a little bit of elbow grease. As far as I know, there isn’t a comparable press for under $1000 in existence.

Higher End (4/4 and 6/6 and up)

The upper end is where things get tricky. Most professionals will agree that, while Riley Hopkins has great lower end options, their 4/2 and 4/4+ manual presses are very overpriced for what they offer. For higher end presses, the best companies to go with are M&R (by a longshot), Workhorse, and Antec. Honorable mentions include Vastex, Hix, and Riley Hopkins.

If you have the money, do some research and buy new. However, this range is a great place to look for used presses. 4/4 and 6/6 presses pop up on the used market all the time, often being sold by screen print supply resellers which fix them up and make sure everything is running smoothly, or just being sold in great conditions by shops that have upgraded. With a little bit of due diligence and potentially a few hours peeking under the hood or adjusting things with a wrench, you can easily land a 5 or 6 thousand dollar press for a quarter of the price.